Cosmetic Liquid Filling Machines – ZONESUN

High-precision, automated filling machines for all cosmetic products

From watery serums to high-viscosity creams.

Ensure hygiene, efficiency, and GMP compliance.

Why Choose ZONESUN Filling Machines?

In the cosmetics industry, packaging reflects product quality, safety, and brand identity. ZONESUN cosmetic filling machines provide precision, automation, and hygiene for skincare and makeup manufacturers.

- Accurate filling for all viscosities

- Multi-container compatibility

- GMP-compliant stainless steel design

- Scalable from small-batch to mass production

Product Features

1. Texture Adaptability

ZONESUN machines handle a wide range of cosmetic textures:

- Watery: toners, serums, floral waters

- Lotion-like: emulsions, primers

- Creamy/Paste: face creams, mascaras

- High-viscosity: eye creams, BB creams

2. Container Compatibility

Supports glass bottles, plastic jars, tubes, and uniquely shaped containers. Quick adjustments for molds and conveyors allow multi-format production.

3. Pump Type Options

| Pump Type | Suitable Viscosity | Applications | Accuracy | Key Features |

|---|---|---|---|---|

| Piston Filling | Medium to High | Creams, lotions | ±1% | High precision, stable for thick products |

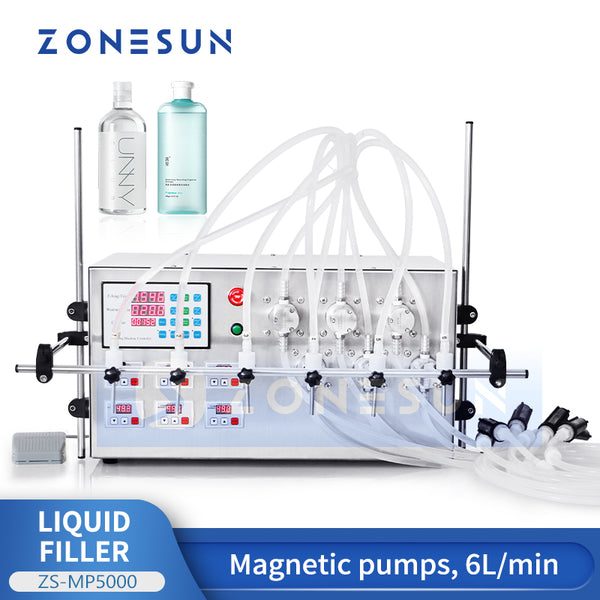

| Peristaltic Pump | Low, Small Doses | Serums, sterile skincare | ±0.5% | Ultra-clean, prevents cross-contamination |

| Rotary Lobe Pump | Thick Paste | Lotions, emulsions, and light creams | ±1% | Simple structure, fast throughput |

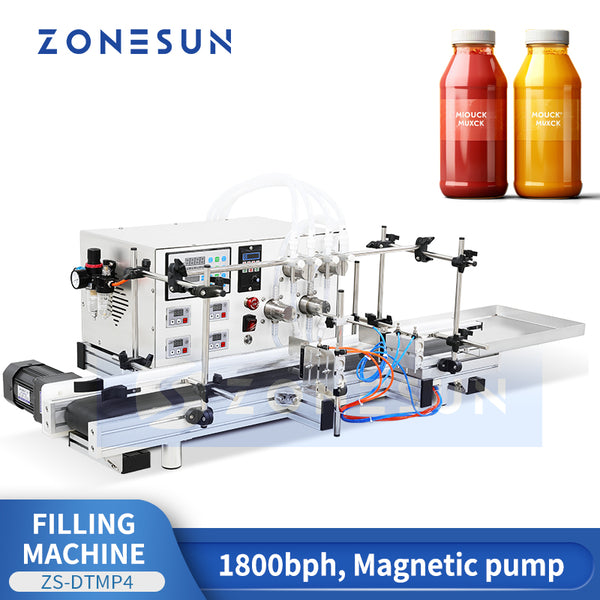

| Magnetic pump | Low to medium | Toners, serums, facial sprays, light lotions | ±1% | Consistent liquid,Leak-free design |

Production Solutions

Small-scale Production

Ideal for startups or custom formulations. Semi-automatic, compact, flexible, and cost-efficient.

Large-scale Production

Fully automated lines integrating bottle unscrambling, filling, capping, and labeling. High-speed, consistent, scalable production.

Automation Advantages

- PLC touch control for easy parameter switching

- Automatic error detection and alerts

- High-speed performance with ≤ ±1% filling error

- Quick changeover between product types and container sizes

Hygiene & Cleaning

- Stainless steel contact parts (304/316), GMP-compliant

- Quick-release components for manual cleaning

- Optional CIP/SIP automated internal cleaning

- Stable, low-maintenance operation

Case 1: Serum Filling (Low Viscosity)

Products: Toners, essences, floral waters

Workflow: Bottle unscrambling → filling → capping → labeling → collection

Advantages: ±0.5% precision, fully automated, compact, GMP-compliant

Case 2: Lotion Filling (Medium Viscosity)

Products: Lotions, emulsions, primers

Workflow: Bottle positioning → piston dosing → filling → capping → labeling( Can Customized Machine For Production Line)

Advantages: ±1% accuracy, high-speed, stable, ideal for large-scale production

Case 3: Cream Filling (High Viscosity)

Products: Face creams, eye creams, thick pastes

Workflow: Container positioning → piston suction → filling → anti-drip → sealing( Can Customized Machine For Production Line)

Advantages: Smooth piston suction, precise, minimal residue, reliable for ic products.

Explore our full range of ZONESUN cosmetic filling machines and beauty packaging solutions.

ZONESUN Technology is a leading manufacturer of cosmetic and personal care packaging machinery, specializing in liquid and paste filling machines for serums, lotions, creams, and high-viscosity products. Our GMP-compliant, automated solutions help brands ensure precision, efficiency, and consistent product quality.

Headquartered in Foshan, Guangdong, China, ZONESUN serves global beauty brands with flexible production solutions, from small-batch artisanal lines to large-scale commercial operations. We are committed to innovation, reliability, and customer-focused support for safe and high-quality cosmetic manufacturing.

📞 Contact Us

- Official Website:https://www.zonesun.com

- Customer Service Email:sales6@zonesun.com

- Tel:+86 189 3431 0866

- Company Address:No. 8, Lane 1, Dongdianbian Road, Nanyue Village, Jinsha Town, Nanhai District, Foshan City, Guangdong Province