ZONESUN ZS-XG16P Automatic Bottle Cap Screwing Capping Machine With Vibratory Bowl

- Prix

- $6,431.99

*NOTE: Please click BUY IT NOW and enter the shipping address to view the SHIPPING COSTS.

Shipping Information

Shipping

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

Payment

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

Product Service

We want you to be happy with your purchase and trying our best to offer the better service to our customers,so we offer some solution if you have below problems or meet below situation:

1. If you received a machine and found the machine was broken :

First,we should note that we will not send any used machine or broken machine to our customers.As we all know,everything will happen during shipping,if your machine is broken,please contact us and help us to complaint this to shipping company.We are here to help you.

2. If you don’t know how to assemble machine or use the machine :

Some of our machine may need you assemble them,or you don’t know how to use the machine,just send us e-mail or message,we will send you video and manual to help you know more about it.

Accuracy, completeness and timeliness of information

We are not responsible for any inaccurate, incomplete or timely information provided on this website. The materials on this website are for general information only and should not be relied upon or used as the sole basis for making decisions without consulting primary, more accurate, complete or timely sources of information. Any reliance on the materials on this website is at your own risk. This website may contain certain historical information. The historical information is not necessarily up to date and is for your reference only. We reserve the right to modify the content of this website at any time, but we are under no obligation to update any information on our website. You agree that it is your responsibility to monitor changes to our website.

Service and price modification

The prices of our products are subject to change without prior notice. We reserve the right to modify or terminate the Services (or any part or content thereof) at any time without notice. We shall not be liable to you or any third party for any modification, price change, suspension or discontinuation of the Services.

Products or Services

Some products or services may be available online only through the website. These products or services may be available in limited quantities and can only be returned or exchanged in accordance with our return policy. We have made every effort to display the colors and images of our products that appear in stores as accurately as possible. We cannot guarantee that any color displayed on your computer monitor is accurate.

ZONESUN TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

No. 8, Lane 1, East Dianbian Road, Shangan Nanyue Village, Jinsha Town, Nanhai Distric, Foshan, 528223 Guangdong, China

About Us

We are a professional packaging machinery production, sales and related technical services of modern high-tech enterprises.

This automatic capping machine is good for various bottles like spray bottles, dropper bottles,trigger pump bottles.It is designed with bottle guiding structure,this is good for bottles that are easy to fall down during capping work,it can improve production quality.This machine is widely used in food,cosmetics,daily chemical industries.

Parameter

Machine model:ZS-XG16P

Bottle height:30-300mm

Cap Diameter:18-70mm

Bottle Diameter:20-160mm

Working speed:20-60 bottles / minute (depending on bottle and cap size and shape)

Working voltage:AC220V/110V 50- 60HZ

Working pressure:0.4-0.6MPa

Machine size: 2420*680*1700mm (machine)+500*500*1640mm(vibratory sorter)

Equipped with vibratory bowl feeder,it can help to arrange and feed bottle caps before capping work,this kind of machine is designed for reducing production labor and error,improves working efficiency.

The bottle guiding structure can be adjusted according to bottle diameter.This is designed for bottles which are easy to fall down during capping work,it can help to transport bottles stably.

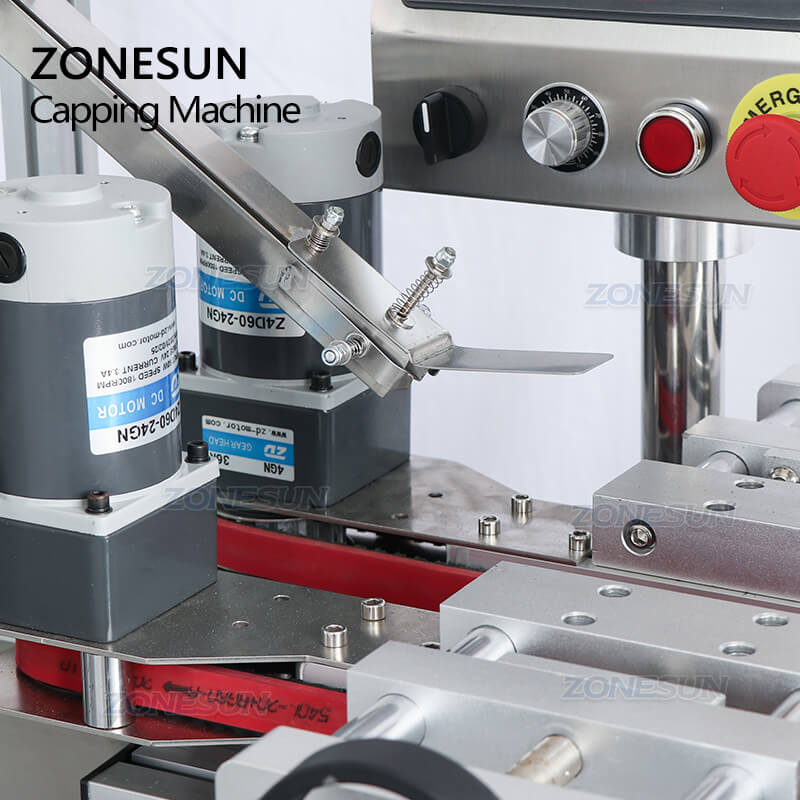

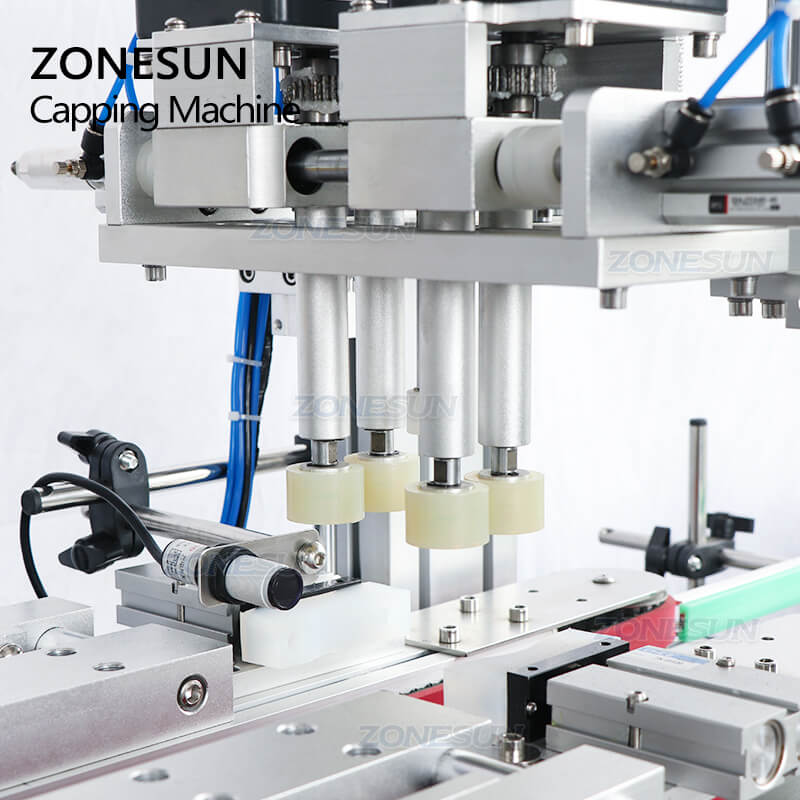

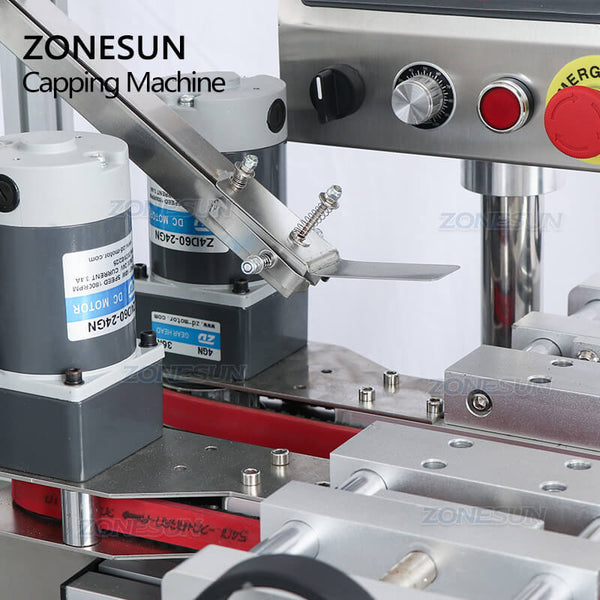

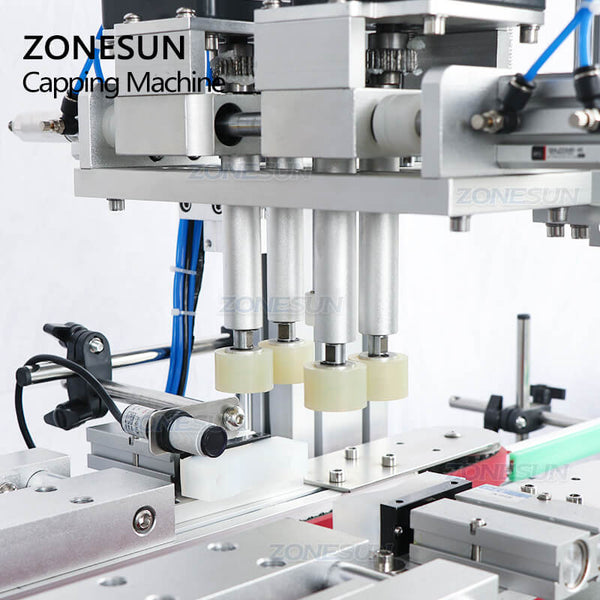

The capping structure is consist of 4 rubber wheels,this kind of capping method makes it suitable for various bottles like trigger pump bottles,dropper bottles,spray bottles,widen the application range.

The electric eye is designed for receiving and send out signal,controlling machine to work or not.With this,the machine can cap bottle precisely and improve production accuracy.

The chain conveyor belt is with large capacity,this makes sure the bottle can be transport stably ,reduce production error.The conveyor width can be customized according to production need.