You may also like

Q&A

This product has not been asked yet

Ask the question

Newest

Enjoy a Special 2% Discount ! Tax-included shipping to the USA available. Contact us.

Please click "Buy It Now". Shipping will be calculated at checkout.

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

In order to offering better service,we have operated with multiple shipping companies like Fedex,DHL,DUP,UPS,EMS etc.We sure that you can choose the most suitable one.For our online products.

When goods are shipped from one country to another, the person who purchases or receives the goods pays import duties. Paying import duties is the responsibility of every citizen, not the seller. Please pay the customs duties in time when receiving the notice. If the buyer does not pay the customs duties, the goods will be destroyed by the customs. The seller will not arrange a refund and the buyer will bear the responsibility. If you need more information about customs duties, please contact your local customs cargo logistics company.

1.Most of them will be shipped by express shipping like Fedex or DHL,delivery time is 6-8 business days.

2.Some small products will be sent by regular shipping,delivery time is 15-45 business days.(There is an instruction saying this product will be sent by regular shipping.)But if you need faster shipping,please contact us to upgrade shipping method.We are glad to help you.

3.Some customers can not place their order since there is an error saying that we can not delivery the product to their countries.If you are in this situation,please contact us to confirm the price and shipping,we will help you place the order successfully .The shipping fee is hard to set up online,and in this situation,it is possible to spend less money to get this product,so it will be better if you can contact us.

4.If you find the shipping fee is too expensive for you,please contact us,we are glad to help you find the best shipping method.For large machine,it will be better for you to contact us before placing the order,in this way we can confirm the price,delivery time and check if the machine is really suitable for your products.

You may find that we only support paypal now,but we can offer other payment method like west union,TT,credit card,wechat pay,Alipay.You will find the best one as your need.If you have any problems about payment,please send us message.Although Some of them are not supported on online service now, we are trying our best to upgrade these.

We want you to be happy with your purchase and trying our best to offer the better service to our customers,so we offer some solution if you have below problems or meet below situation:

1. If you received a machine and found the machine was broken :

First,we should note that we will not send any used machine or broken machine to our customers.As we all know,everything will happen during shipping,if your machine is broken,please contact us and help us to complaint this to shipping company.We are here to help you.

2. If you don’t know how to assemble machine or use the machine :

Some of our machine may need you assemble them,or you don’t know how to use the machine,just send us e-mail or message,we will send you video and manual to help you know more about it.

We are not responsible for any inaccurate, incomplete or timely information provided on this website. The materials on this website are for general information only and should not be relied upon or used as the sole basis for making decisions without consulting primary, more accurate, complete or timely sources of information. Any reliance on the materials on this website is at your own risk. This website may contain certain historical information. The historical information is not necessarily up to date and is for your reference only. We reserve the right to modify the content of this website at any time, but we are under no obligation to update any information on our website. You agree that it is your responsibility to monitor changes to our website.

Service and price modification

The prices of our products are subject to change without prior notice. We reserve the right to modify or terminate the Services (or any part or content thereof) at any time without notice. We shall not be liable to you or any third party for any modification, price change, suspension or discontinuation of the Services.

Products or Services

Some products or services may be available online only through the website. These products or services may be available in limited quantities and can only be returned or exchanged in accordance with our return policy. We have made every effort to display the colors and images of our products that appear in stores as accurately as possible. We cannot guarantee that any color displayed on your computer monitor is accurate.

ZONESUN TECHNOLOGY LIMITED

[Re: Privacy Compliance Officer]

No. 8, Lane 1, East Dianbian Road, Shangan Nanyue Village, Jinsha Town, Nanhai Distric, Foshan, 528223 Guangdong, China

We are a professional packaging machinery production, sales and related technical services of modern high-tech enterprises.

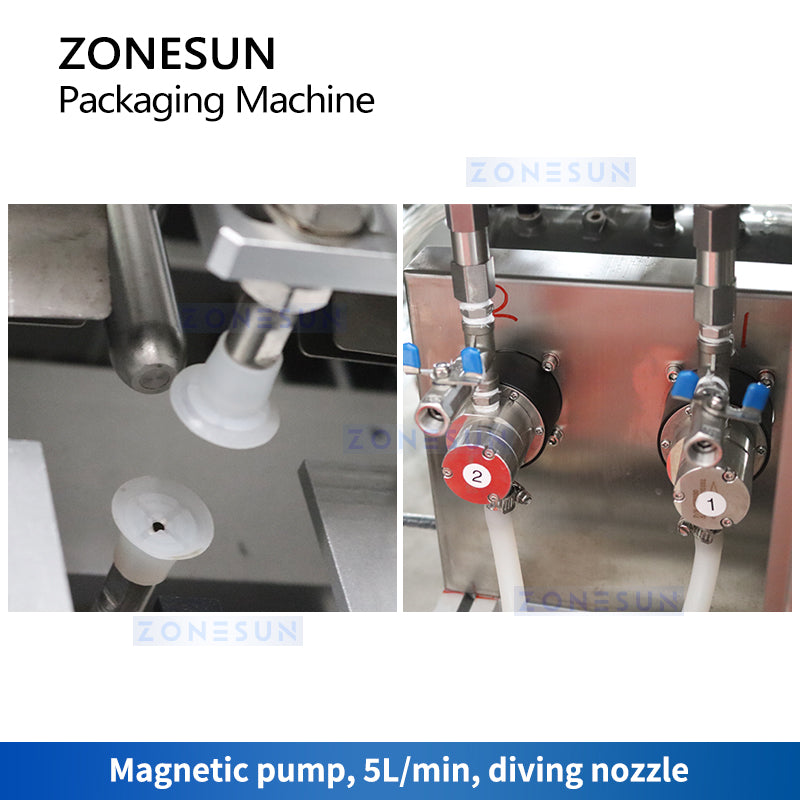

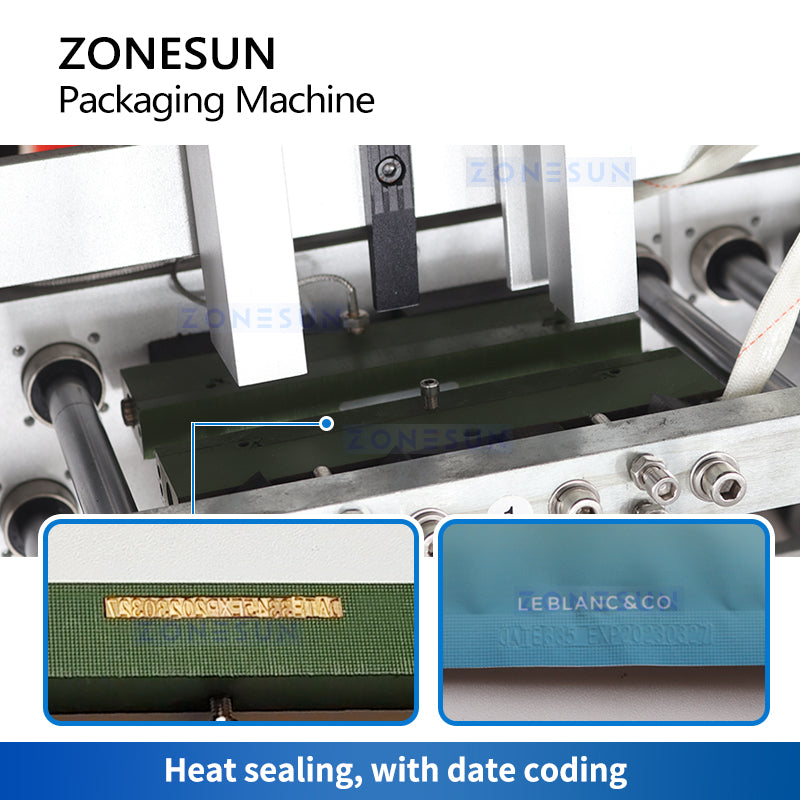

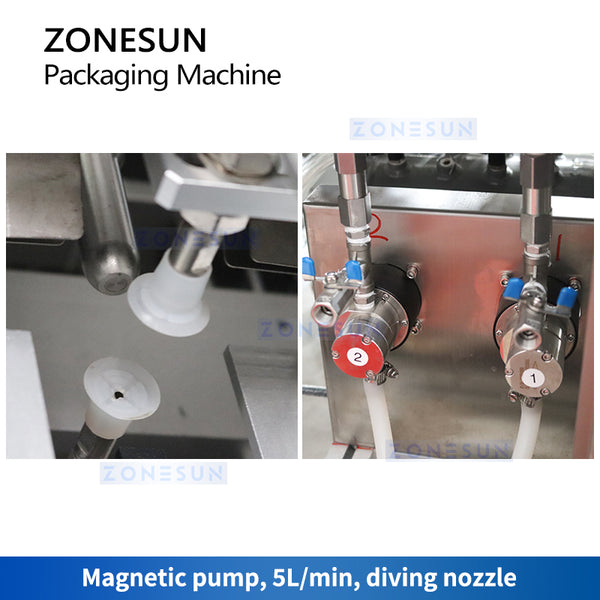

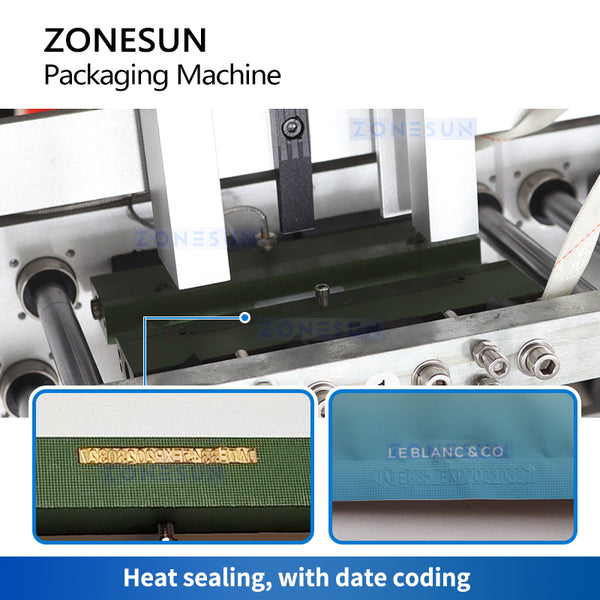

The ZONESUN ZS‑MS2TGF Full Automatic 2‑Nozzle Facial Mask Packing Machine is designed for high‑efficiency liquid bag filling and sealing. Featuring a dual‑channel bag holder, it ensures stable positioning during the filling process. The magnetic pump dispenses liquids with ±0.3 g accuracy at a rate of up to 5 L/min, making it ideal for small‑dose packaging from 1 g to 50 g.

Bags are filled at speeds of 1800–2880 pcs/h, heat‑sealed with advanced sealing jaws, and date‑coded for traceability before being transferred via conveyor for collection. Suitable for cosmetic and personal care production lines, this machine delivers consistent performance, reduced product waste, and streamlined operations.

Note: Requires an air supply of 0.6–0.8 MPa. Images shown are for reference only.

|

Machine model |

ZS-MS2TGF |

|

Machine voltage |

220V 50-60Hz |

|

Machine power |

About 1KW |

|

Working speed |

1800-2880 pieces/h |

|

Bagging size |

130-230mm*80-160mm(L*W) |

|

Range |

1-50g |

|

Pump |

Magnetic pump |

|

Filling rate |

5L/min |

|

Filling accuracy |

±0.3g |

|

Air pressure |

0.6-0.8Mpa |

|

Air consumption |

150L/h |

|

Air inlet |

Diameter: 12mm |

|

Machine size |

About 700*800*1450mm(L*W*H) |

|

Machine weight |

About 120kg |

|

ATTENTION |

|

|

All images are for illustration purposes only and actual products may vary due to product enhancement or change. |

|

ZONESUN Packaging Machinery--

12 years experience

Office area 8,600 ㎡

131 employees, 52 engineers

offer ODM or OEM

Contace us to get more surprise:

TIM: sales6@zonesun.com

Whatsapp: 0086 18934310866

© 2025, ZONESUN OFFICIAL STORE Szolgáltató: Shopify